Revolutionizing the Quality and Efficiency of Endplate Analysis

Automating Endplate Testing for Railway Sleeper Beds

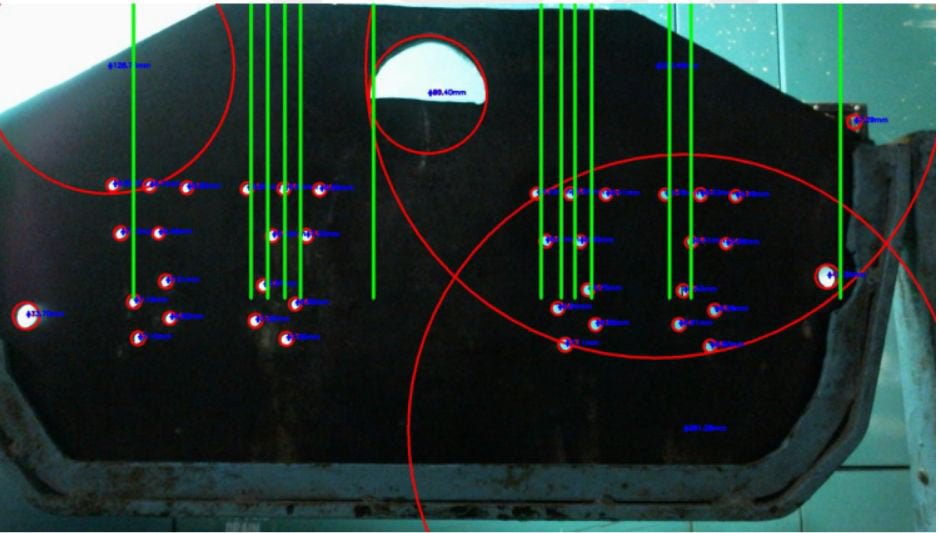

A manufacturing giant in India produces end plates for railway beds, and each plate is manually tested for its radius size by fitting a test gauge inside it. The testing process takes between 10 minutes for each plate, and thousands of endplates are tested every day. The manual process is time-consuming and prone to human error.

Problem

A manufacturing giant in India produces end plates for railway beds, and each plate is manually tested for its radius size by fitting a test gauge inside it. The testing process takes between 10 minutes for each plate, and thousands of endplates are tested every day. The manual process is time-consuming and prone to human error.

Key Requirements

- Develop a solution that will automate the testing process

- Accurately find the radius of the holes in the endplates

- Reduce the testing time by 10x

- Create a database to store the details of each endplate for future reference

- Ensure the solution works in the specific environment and conditions of the manufacturing plant

Testing Process

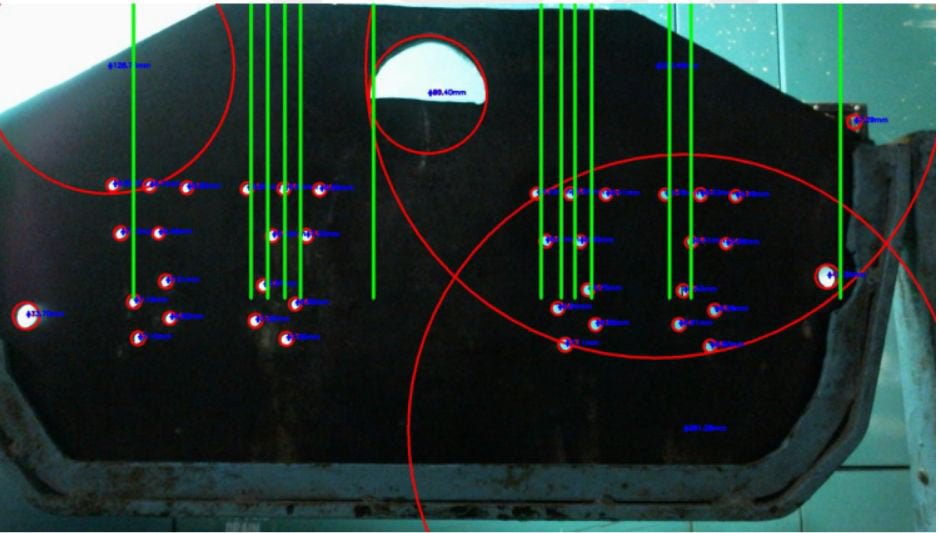

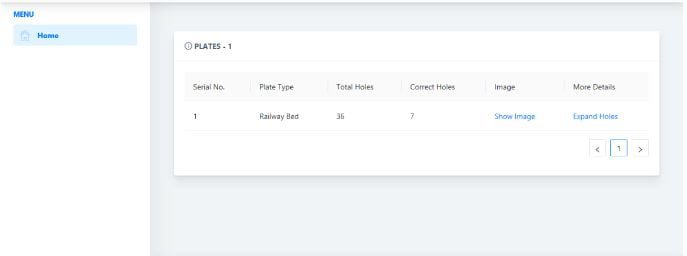

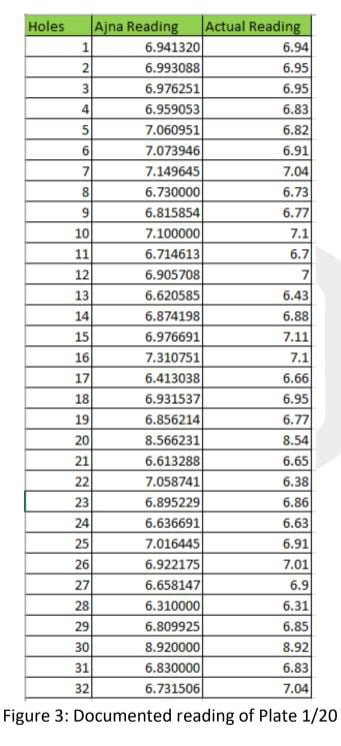

The algorithm was tested on 20 plates, and training was provided to the concerned personnel. The setup was installed at a new location, considering proper lighting conditions, easy usability, and network access. Vernier caliper readings were shared with us by the plant team to analyze performance. UI changes were made to enhance usage and reporting. Calibration of other plate types was done by the team at the plant.

Results

The solution developed by our team revolutionizes the quality and efficiency of endplate analysis. The automated testing system accurately finds the radius of the holes in the endplates and reduces the testing time by 10x. The database and dashboard provide a centralized system for storing and accessing endplate details, making the testing process more organized and efficient. The lot with defective holes is identified and sent for fixing/re-boring, improving the quality of the endplates and, ultimately, the railway sleeper beds.

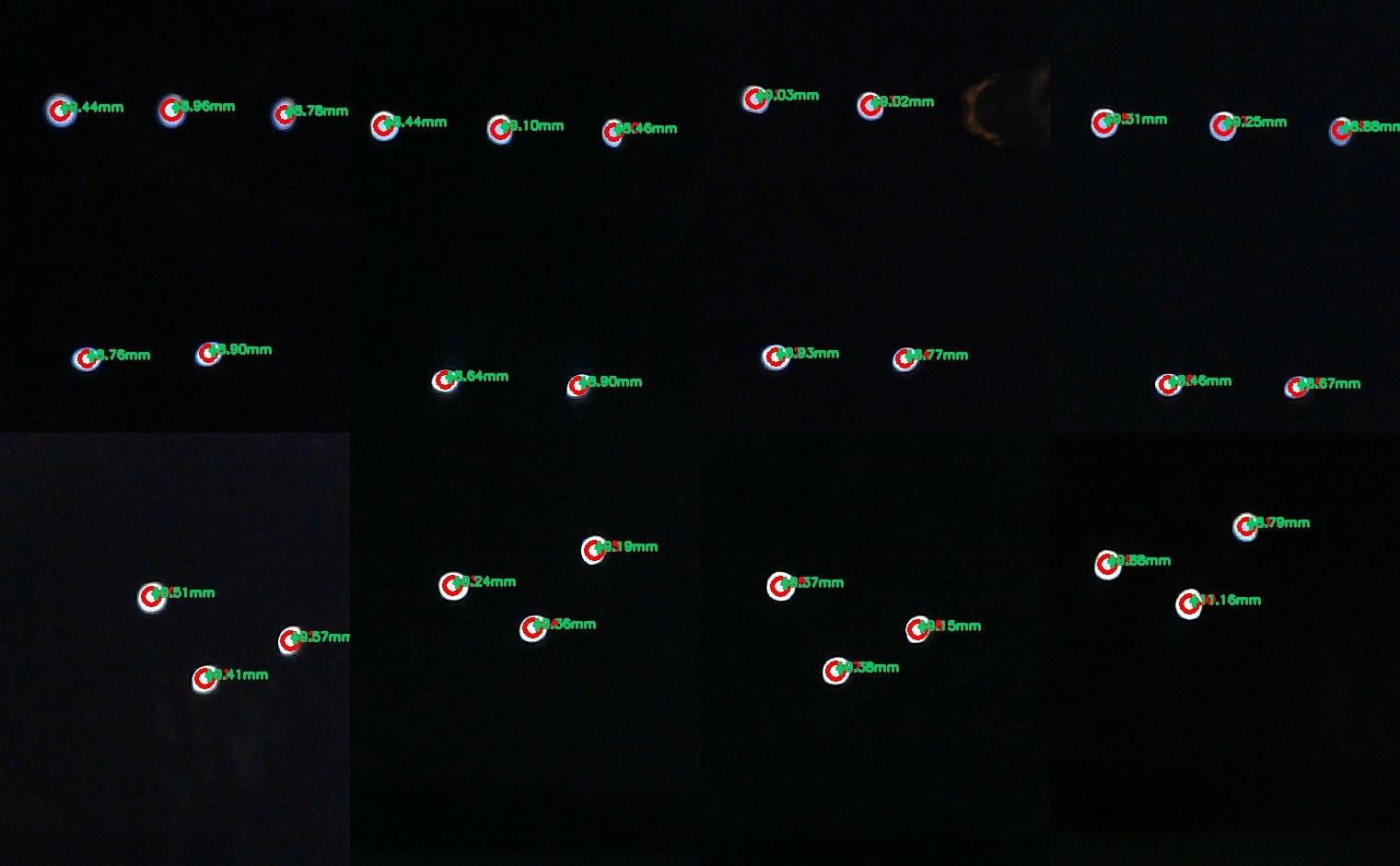

Logic

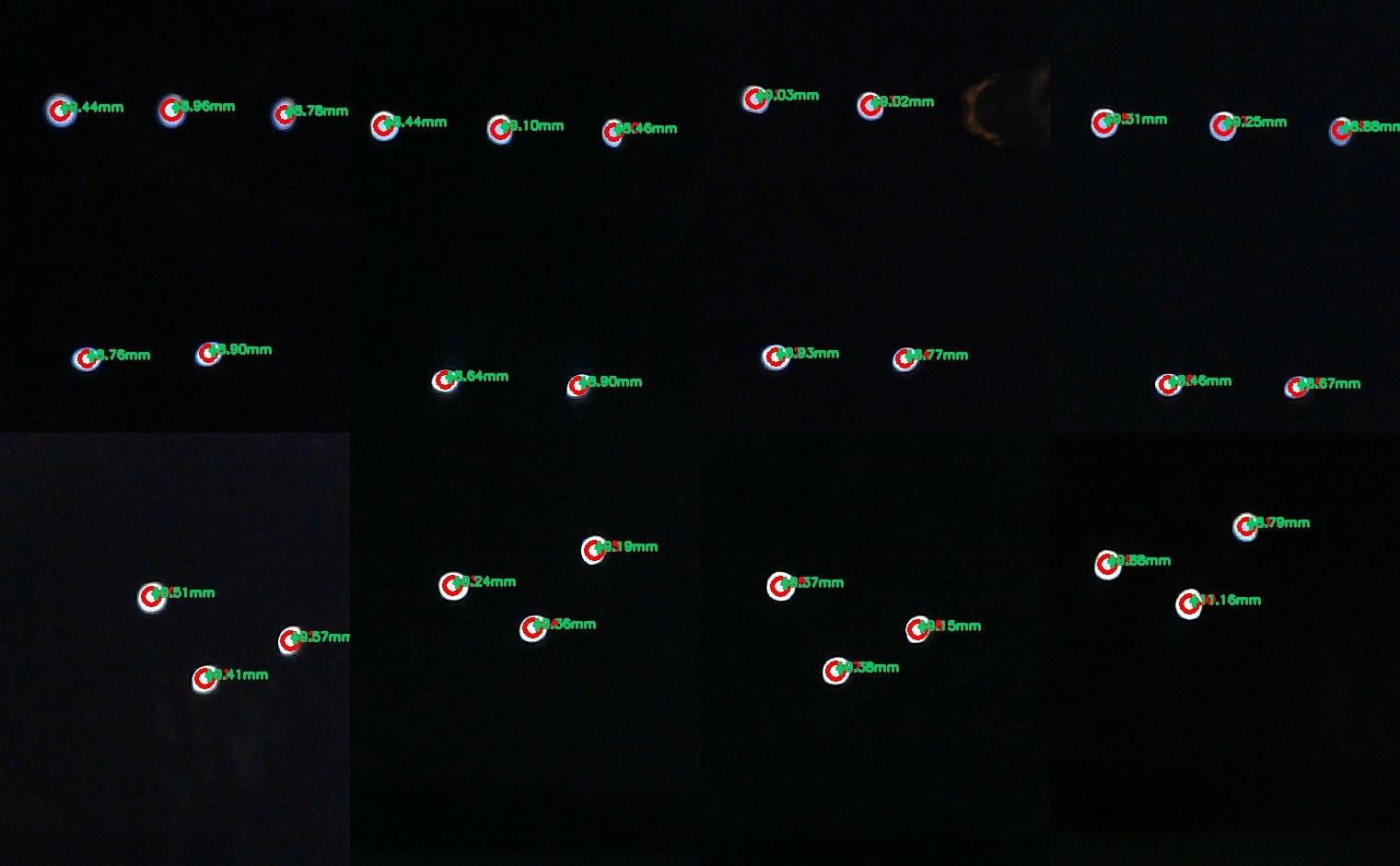

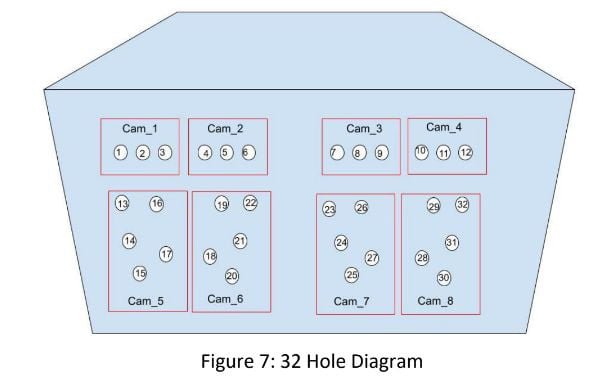

The solution consists of a hardware and software setup. A grid of cameras is placed above the endplate, and the cameras instantly detect the holes and estimate the radius accurately. The grid stand is calibrated for first-time usage, and the details of each endplate are updated to the database, which can be viewed from the dashboard.

Services

- Automated Endplate Testing System

- Calibration of Endplate Testing System

- Database Setup and Management

- Dashboard Setup and Management